System

At Stancer Testing-Lab, our system testing services go beyond verifying individual parts, we ensure your entire system operates seamlessly, mitigating risks, enhancing reliability, and protecting your brand’s reputation. By evaluating both individual components and their collective performance, we identify and resolve potential issues before they impact your market success, ensuring compliance with global standards and unparalleled system performance.

- Services

- System

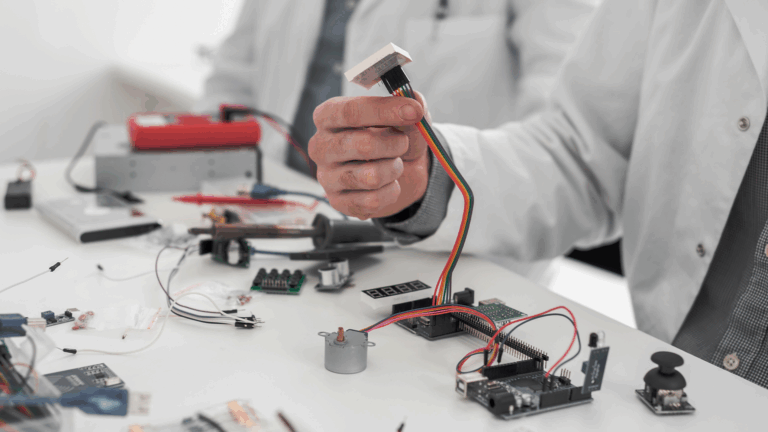

In modern technologies, individual components may perform well in isolation, but integration into a complete system can create additional challenges. System testing evaluates the interaction of hardware, software, and subsystems to verify that the overall solution functions as intended. This process reduces risk, improves reliability, and supports compliance with applicable international standards.

Expertise in System Integration

Our engineers and compliance specialists have experience in assessing complex systems across multiple industries, including consumer electronics, IoT ecosystems, industrial automation, and medical devices. With accreditations recognized in North America, Europe, and other international markets, we provide testing services aligned with standards such as EMC, RF, safety, and environmental requirements. Certification pathways include FCC, CE, ISED, and ISO, ensuring readiness for global distribution.

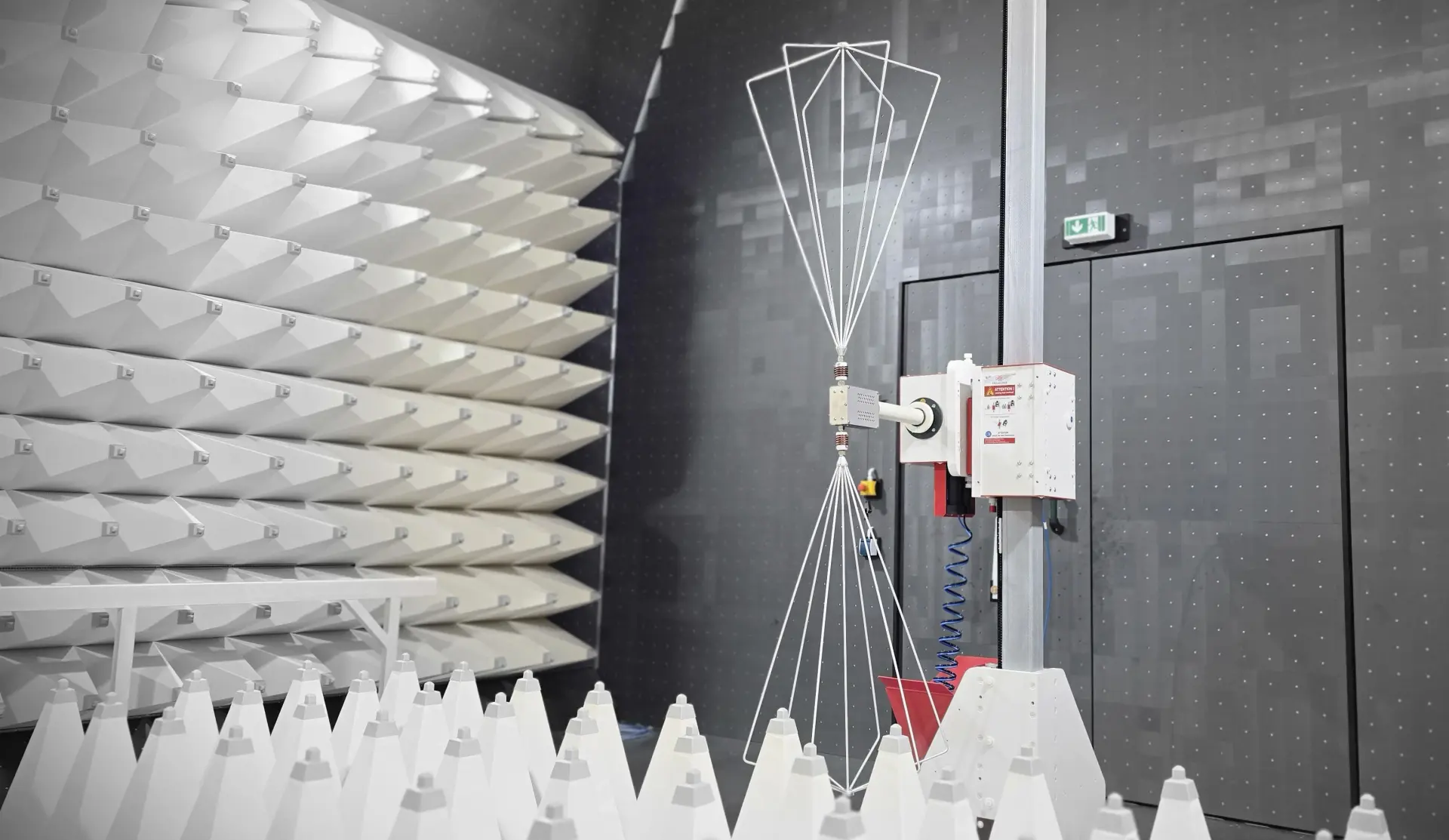

Facilities for System-Level Validation

Testing is carried out in controlled environments designed for system-wide assessment. Facilities include EMC chambers, RF laboratories, interoperability platforms, and environmental simulation equipment. These resources make it possible to replicate operational conditions and evaluate system behavior under different stress factors. Applications range from 5G-enabled devices to renewable energy systems.

Testing Workflow

Projects are supported by structured workflows that combine pre-compliance evaluations with comprehensive system-level testing. Early identification of potential integration issues helps avoid delays and reduces development costs. Testing protocols are tailored to product-specific requirements, while maintaining alignment with global regulatory frameworks.

Project Support and Reporting

Dedicated project managers coordinate scheduling, documentation, and communication throughout the testing process. Detailed reports are issued in formats suitable for regulatory submission and internal engineering review, providing technical findings and recommendations for system optimization.

Focus Areas

System-wide EMC and RF testing for interoperability and compliance

Functional safety evaluation under realistic operational conditions

Environmental stress testing including thermal, humidity, and vibration scenarios

Specialized testing for IoT, 5G, and automation technologies

Sustainability Considerations

Environmental compliance is integrated into the testing process, supporting industry requirements for eco-design and sustainability. Testing methods are adapted to verify alignment with global environmental standards where required.

Have Questions? Let’s talk

Get in touch, and we’ll be happy to assist you with your questions or needs.

Related Articles

EMC Testing At Stancer Testing-Lab, we offer comprehensive EMC testing services to enhance product performance

At Stancer Testing-Lab, we transform the complex world of submission and registration into a clear,

Our world-class testing and certification services ensure your products surpass the most rigorous international standards

At Stancer Testing-Lab, we are committed to a detailed and efficient testing process, ensuring your