As a manufacturer, ensuring your products meet the required electromagnetic compatibility (EMC) standards is crucial. Failing to pass EMC tests can delay your product’s release, cause compliance issues, or even lead to costly recalls. However, achieving accurate and reliable results from EMC testing depends on several factors, including the environment in which testing is conducted, the equipment used, and the proper execution of procedures. In this blog, we’ll discuss how environmental factors can affect results and guide you on how to choose the right EMC lab to ensure that your product’s performance meets industry standards.

Environmental Factors and Their Impact on EMC Testing

The environment in which EMC testing is conducted can significantly influence the results. Small fluctuations in temperature, humidity, or even nearby electromagnetic interference can lead to inaccurate data, which may affect the compliance of your product. Understanding how environmental conditions impact testing is essential to ensuring you get reliable results.

Temperature and Humidity Control

Temperature and humidity are key environmental factors that affect both the device under test (DUT) and the testing equipment. For instance, high humidity levels may cause short-circuits or affect the insulation resistance of components, while extreme temperatures can alter the performance of semiconductors or the behavior of materials under test. These factors need to be carefully controlled to ensure that the results reflect real-world performance.

Shielding and External Interference

Electromagnetic interference (EMI) from nearby electronic devices, power lines, or wireless signals can contaminate the test results. A well-shielded environment is essential to prevent external signals from interfering with the test. Ensuring that the test environment is free from such interference is vital to obtaining accurate results that reflect the true electromagnetic compatibility of your product.

Regular Equipment Calibration

Test equipment such as spectrum analyzers, field generators, and antennas must be properly calibrated. Without regular calibration, you risk inaccurate measurements, which could result in unnecessary adjustments to your product or failure to detect potential EMC issues. Calibration ensures that equipment is performing within the expected accuracy, and regular maintenance helps keep it in optimal working condition.

How to Minimize the Risk of Unreliable Results

EMC testing is only reliable if the procedures are followed correctly and the test setup is appropriately configured. Inaccurate results can stem from improperly conducted tests, faulty equipment, or incorrect measurement methods. As a manufacturer, you must be vigilant about minimizing these risks by ensuring proper setup and adherence to standards.

Follow Standardized Test Protocols

Ensure that the EMC lab follows standardized test protocols as outlined by relevant international guidelines like IEC, ISO, or CISPR. These standards provide the framework for how the tests should be set up, conducted, and analyzed. A consistent approach helps eliminate variability in results and ensures they are meaningful.

Use Comprehensive Test Configurations

Performing EMC tests in a real-world scenario often involves more than a single configuration. Test your product at different frequencies, power levels, and operating conditions. This approach ensures the results accurately represent how the product will perform in diverse electromagnetic environments.

Consistent Measurement Practices

Measurement techniques must be standardized. For example, the placement of probes, antennas, and the DUT must follow established guidelines. Even minor deviations can lead to variations in results. Ensuring a repeatable, consistent method across tests is crucial to obtaining reliable data.

Choosing the Right EMC Lab for Your Testing Needs

Selecting the right EMC lab is one of the most critical decisions you’ll make in the testing process. The lab you choose will directly impact the accuracy and reliability of your test results. Here are the key factors you should consider when evaluating a lab for your product’s EMC testing:

- Accreditation and Compliance with Standards

Look for labs that are accredited by recognized bodies, such as ISO/IEC 17025. This accreditation ensures that the lab follows internationally recognized procedures and meets stringent quality control measures. Accreditation also provides assurance that the lab’s results are valid and accepted worldwide.

- Expertise in Your Industry

It’s important to choose a lab with expertise in testing products similar to yours. Whether you’re testing consumer electronics, automotive components, or medical devices, ensure that the lab has experience with your type of product. A lab familiar with your industry will better understand the specific challenges and requirements of your product.

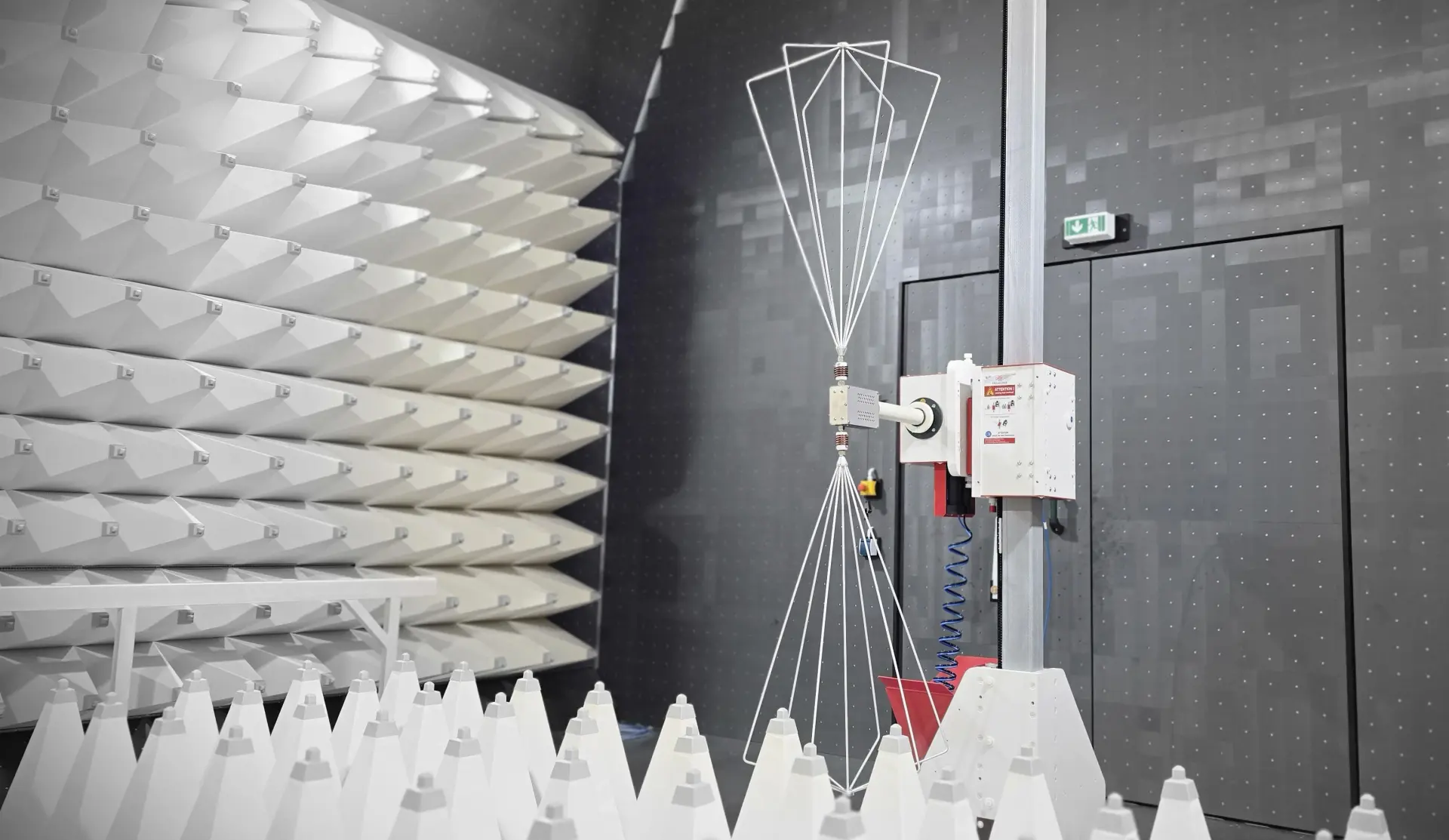

- Advanced and Up-to-Date Equipment

The lab should be equipped with state-of-the-art testing facilities, such as anechoic chambers, field generators, and spectrum analyzers. Ensure that the lab uses the latest technology, which improves the accuracy and reliability of the testing process. An outdated setup can lead to errors or an inability to test certain frequencies or emissions.

- Control Over Environmental Conditions

Make sure the lab has measures in place to control environmental factors such as temperature, humidity, and external electromagnetic interference. A well-controlled environment reduces the likelihood of skewed results and helps ensure that the tests reflect real-world conditions.

- Clear and Detailed Reporting

A good EMC lab should provide you with detailed test reports that include not only the results but also an explanation of the testing methods, conditions, and any issues that may have affected the results. This transparency allows you to understand your product’s performance and make necessary adjustments or improvements.

Conclusion

As a manufacturer, ensuring that your products meet EMC standards is vital for regulatory compliance and market success. The accuracy of your EMC testing results is influenced by several factors, from the environmental conditions during the test to the expertise and equipment of the lab conducting the test. By selecting a reliable EMC lab and understanding the importance of test setup and environmental control, you can ensure that your product performs as expected in the real world, passes required tests, and avoids costly delays or issues down the road.

Choosing the right EMC lab is an investment in your product’s quality, and ultimately, its market readiness. Make sure to take the time to select a lab that meets all of your testing needs and provides reliable, accurate results.

Related Articles

Stancer Testing-Lab specializes in validating Electromagnetic Compatibility (EMC) test sites, ensuring your Open Area Test

EMC Testing At Stancer Testing-Lab, we offer comprehensive EMC testing services to enhance product performance

At Stancer Testing-Lab, our system testing services go beyond verifying individual parts, we ensure your

Our world-class testing and certification services ensure your products surpass the most rigorous international standards